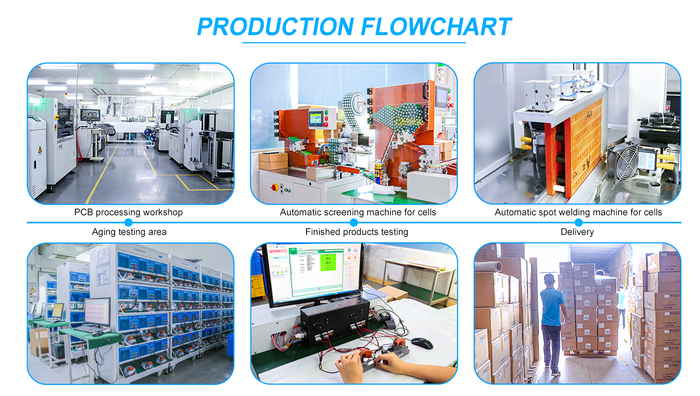

Company Profile

About XNJTG

Powering innovation, powering the future

Since 2010, XNJTG has been at the forefront of battery innovation, providing reliable and efficient power solutions to customers around the world. Our mission is to power innovation and drive progress, and we are dedicated to creating a future that is powered by clean energy.

Our story

Innovation Driving Progress Since 2010

Our values

Responsibility, Sharing, Initiative

At XNJTG, our commitment to responsibility and sharing drives us to create reliable and efficient power solutions that power progress and drive innovation forward.

R&D team

Leading with Vision, Driving Results

XNJTG is dedicated to developing advanced lithium-ion battery technology that provides reliable and efficient power, while reducing environmental impact. Join us in driving progress and shaping a greener future.

WHY XNJTG

Where innovation meets precision

- Customer Supreme

- Quality Paramount

- Embrace Innovation, Strive for Excellence

- Strive for Excellence

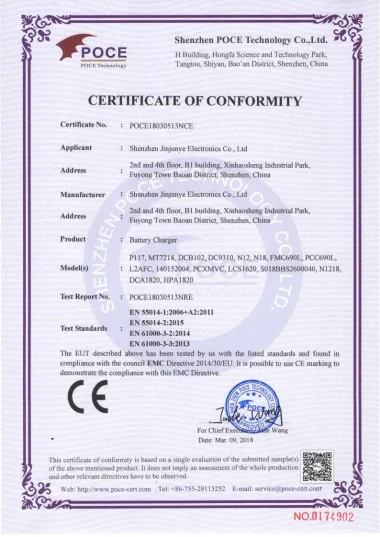

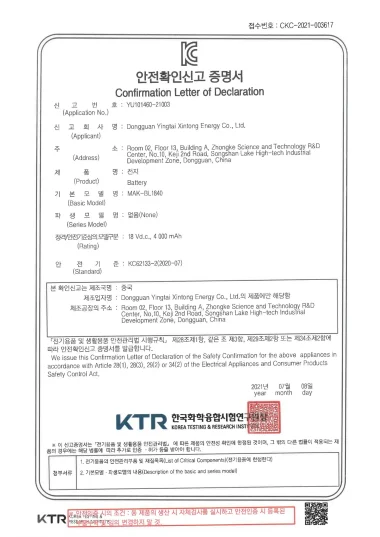

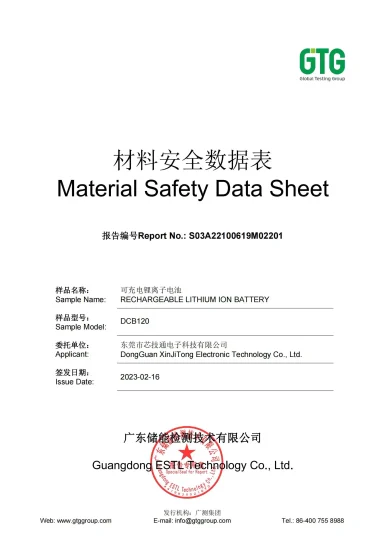

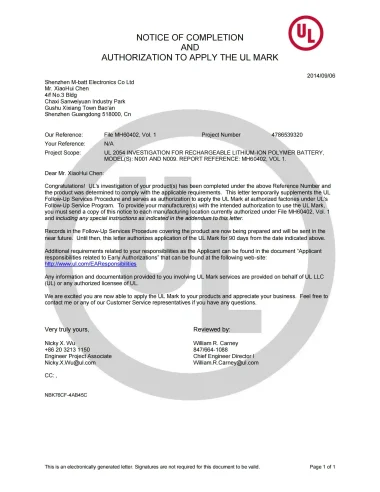

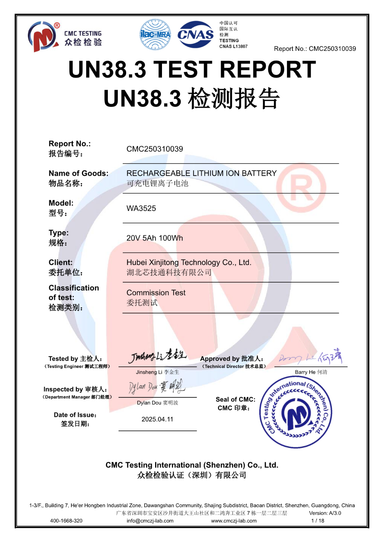

Certifications

Trust XNJTG for the highest standards of quality and compliance

XNJTG is dedicated to developing advanced lithium-ion battery technology that provides reliable and efficient power, while reducing environmental impact. Join us in driving progress and shaping a greener future.

Insights

Latest News

The latest industry news, interviews, technologies and resources.

Let our battery power your success

Transform your path to success with our advanced battery technologies, while enjoying the perks of free technical guidance and tailored design services to meet your unique requirements.