Custom solutions

Comprehensive custom battery solutions for every need

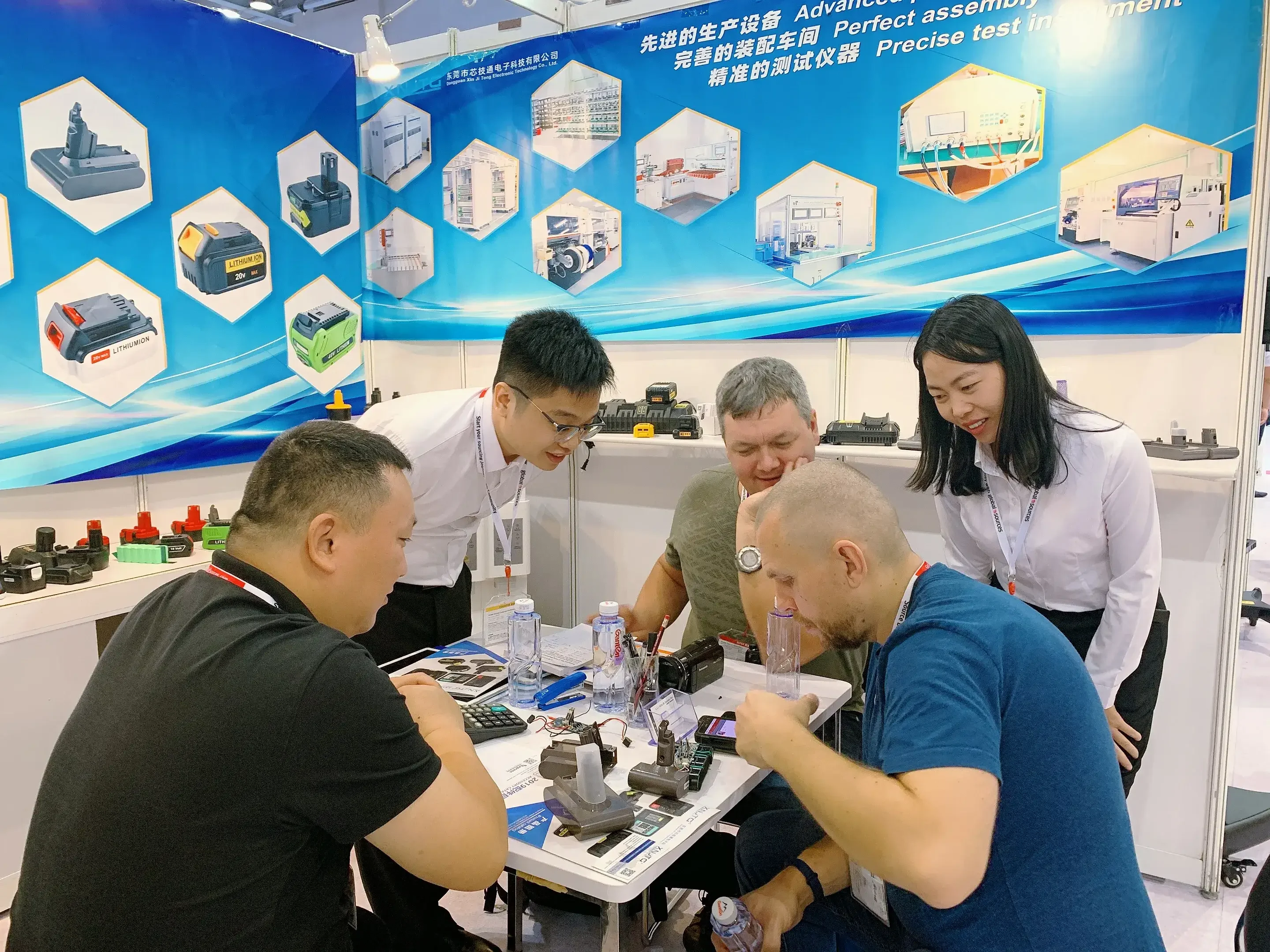

Covering various industries and applications, XNJTG provides exceptional custom battery pack solutions, designed for consistent and reliable performance tailored to your specific power needs.

Requirement analysis

Understand the specific needs & requirements for your project

XNJTG provides engineers with over 10 years of experience in customizing battery packs, chargers, and tooling. Inquire with our specialists for more details.

Battery pack design

Develop battery pack that aligns with your requirements

This involves determining the optimal arrangement of battery cells within the pack, designing the physical enclosure or housing, selecting appropriate connectors and wiring, and incorporating safety features such as thermal protection and overcharge/over-discharge protection circuits.

- Cell arrangement

- Mechanical support

- Thermal management

BMS design

Battery Management System Design

We design the BMS to monitor and protect the battery pack, ensuring optimal performance and safety under different operating conditions.

- Overcurrent protection

- Overcharge protection

- Over discharge protection

- Short circuit protection

- Temperature control

- Voltage balance

Charger design

Good batteries need good chargers to perform at their best

We design our chargers according to the battery pack type and capacity to ensure optimal charging performance and meet the unique charging needs of the battery pack.

- Charging rate

- Charging time

- Energy efficiency

Application testing

Certification and Compliance made easy

We assist in obtaining necessary certifications such as CE, UL, KC, PSE and RoHS, and coordinate compliance testing for transportation regulations like UN38.3 for safe battery shipping.

Warehousing & logistics

Flexible, efficient, cost-effective for a seamless supply chain

With our worldwide warehousing and logistics network, we provide streamlined logistics solutions that ensure a seamless supply chain, no matter where your business takes you.

After-sales support

It doesn't end at the sale, it's just the beginning.

Provide ongoing support to address any issues or inquiries from the customer. This includes troubleshooting assistance, repair or replacement services for faulty packs, and offering maintenance guidelines to maximize the lifespan and performance of the battery packs.

Custom development process

Custom Battery Pack Development Process

- Initial Consultation: We begin by understanding your specific power requirements, application needs, and any special considerations such as size constraints or environmental factors.

- Design Proposal: Based on the consultation, we provide a detailed design proposal outlining the optimal arrangement of battery cells, physical enclosure design, connectors, wiring, and safety features.

- 3D Sample Confirmation: After rigorous testing for performance and safety, we ship out a 3D sample and await your confirmation.

- Production Initiation: Upon receipt of a 30% deposit, we initiate sample production.

- Sample Confirmation: Before final production, we provide samples for your confirmation, allowing you to review and validate the design and functionality of the custom battery pack.

- Production and Assembly: Upon successful sample confirmation, we proceed with mass production and assembly of the custom battery packs, maintaining strict quality control throughout the process.

- Balance Payment and Delivery: After production completion, we request the balance payment. Upon receipt, we arrange for the delivery of your custom battery packs, ensuring timely and secure shipment.

- Ongoing Support: We provide ongoing support, including troubleshooting assistance, repair or replacement services for faulty packs, and offering maintenance guidelines to maximize the lifespan and performance of the battery packs.

Our comprehensive custom battery pack development process ensures that you receive a high-quality, reliable, and tailored solution that meets your specific power needs and application requirements.

Custom Pcb Assembly development process

1. Our team confirms the necessary files and order details.

2. Manufacture SMT stencil (if needed).

3. Program our machines from the BOM and Centroid file, before the materials arrive. Discrepancies found in the files will be addressed.

4. After all the materials are received, our team performs a kit audit of the materials. Discrepancies or additional questions will be addressed. Before the assembly lead time begins we must have all questions answered.

5. If all materials are in before 12pm PST, the assembly lead time starts the next business day. Materials received after 12pm PST will be considered received on the next business day. The reason for this is to allow proper time for the materials to go through the kit audit process.

6. The SMT components are assembled first with our automated equipment. The first board goes through extensive QA to assure part placement and polarity are correct. The boards are then inspected (visually and with an AOI machine) as they come off the reflow oven.

7. BGA components are X-rayed to verify placement accuracy and to detect any solder bridges.

8. After SMT the boards are washed when applicable.

9. Thru-hole components are inserted and soldered by hand or with a selective soldering machine depending on the quantity and board design.

10. After thru-hole boards are washed again when applicable.

11. A final quality inspection is performed.

12. The finished PC board assemblies and all extra materials are prepped for packaging.

Industries

Discover the power of our batteries for your industry

Explore the various sectors that our dependable battery solutions have successfully powered, discover how our expertise can accelerate your business growth, and let's discuss your industry's unique needs.

FAQs

We answer some of the questions we frequently receive to help you better understand our services and products. If you have any other questions, please don't hesitate to contact us.

What is battery pack application testing?

Inspection of raw materials, capacity sorting of battery cells, selection of battery cells, inspection of protective boards, inspection of battery packs, charging inspection, discharge testing, refinement testing, finished product inspection, and outbound inspection are the ten processes of detection. If you have any other questions, please feel free to contact us.

What certifications can you assist in obtaining for my battery pack?

MSDS UN38.3 CE, UL,KC,PSE and RoHS,and you need more, please feel free to contact us.

What after-sales service do you provide for battery packs?

We offer a 13-month warranty period, and the specific warranty terms depend on whether the batteries are shipped by air or sea. If shipped by air, we will replace any non-man-made damage within 3 months by providing new batteries in the next order. For sea shipments, the warranty period is extended to 4 months, within which non-man-made damage will be compensated with new batteries in the next order. After 4 months, the replacement policy will be based on a depreciation rate.

How can your team help me grow my business with battery packs ?

Our battery protection boards are equipped with various protective functions, such as overcharge protection, over-discharge protection, over-temperature protection, over-current protection, as well as dual-cell and single-cell balancing protection, and short-circuit protection. Our plastic casings are made of V0, the highest-grade fire-resistant material, ensuring comprehensive battery safety;

We offer long battery life and guaranteed after-sales service;

Independent Research and Development, Self-Production, and More Competitive Pricing

The Super Factory provides a guaranteed capacity with a short delivery time, ensuring timely and efficient fulfillment of production needs.

Let our battery power your success

Transform your path to success with our advanced battery technologies, while enjoying the perks of free technical guidance and tailored design services to meet your unique requirements.