How to Choose a Long‑Lasting Battery for Power Tools: Energy Density Explained

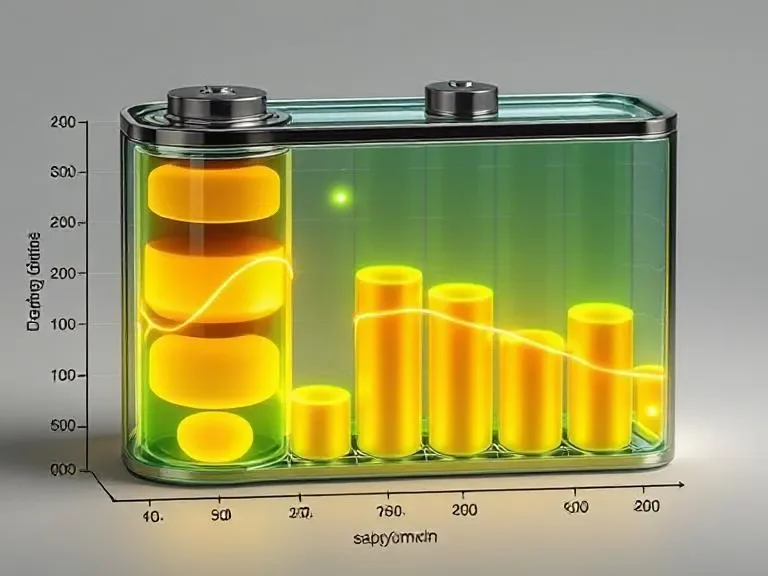

In portable power tools, energy density—the amount of energy stored per unit of weight (Wh/kg) or volume (Wh/L)—is the single most important metric for maximizing runtime without making your tool unwieldy. This guide explains why focusing solely on amp-hours (Ah) can lead to selection mistakes and shows you how to pick a battery that truly lasts.

1. What Is Battery Energy Density?

Gravimetric Energy Density (Wh/kg): Watt‑hours per kilogram of battery weight.

Volumetric Energy Density (Wh/L): Watt‑hours per liter of pack volume.

> Why it matters: A 4 Ah pack built with high-density cells will run your drill longer and weigh less than a 4 Ah pack of lower-density chemistry.

HIT-BCL18-LI Lithium-Ion Battery For Hitachi BCL, EBM Power Tools

2. Why You Need High Energy Density

- Longer run times on a single charge—fewer interruptions on the job.

- Lighter tools reduce operator fatigue and improve maneuverability.

- Fewer pack swaps mean smoother workflow and higher productivity.

> Key takeaway: In most cordless tool applications, a battery’s weight matters as much as its raw capacity.

3. Top Battery Chemistries by Energy Density

Compare the gravimetric ranges of leading lithium‑ion chemistries:

| Chemistry | Gravimetric Density (Wh/kg) | Notes |

| LCO | 200–260 | Highest energy, moderate cycle life |

| NMC | 150–220 | Balanced energy & safety |

| LFP | 90–120 | Lowest density, exceptional safety |

| LTO | 70–100 | Ultra‑long cycle life, bulky |

> Big picture: LCO delivers the most energy per weight, but often at the expense of cost and thermal stability.

4. Overview of Main Li‑Ion Cell Types

LTO (Lithium Titanate): \~70–100 Wh/kg, >10,000 cycles, extreme safety, bulky.

LCO (Lithium Cobalt Oxide): \~200–260 Wh/kg, premium runtime, heat-sensitive, shorter life.

NMC (Nickel Manganese Cobalt): \~150–220 Wh/kg, the “sweet spot” for tools—good energy, safety, and cost balance.

LFP (Lithium Iron Phosphate): \~90–120 Wh/kg, industry-leading safety and 2,000+ cycles, heavier per Wh.

5. Matching Chemistry to Your Needs

- High Runtime Demands: LCO if weight budget allows and you have robust thermal control.

- All‑Around Performance: NMC for balanced energy, safety, and lifespan.

- Safety & Cycle Life Priority: LFP for workplace tools where durability and thermal stability are critical.

6. Frequently Asked Questions

Q1: Which chemistry offers the highest Wh/kg?

LCO cells lead, but require high-quality BMS and heat management.

Q2: How do I balance energy density with cycle life?

Choose NMC or LFP—NMC for more energy, LFP for maximum longevity and safety.

Q3: Does higher Ah always mean longer runtime?

Yes for the same load, but energy density (Wh/kg) tells you how much capacity you get per weight.

Q4: What else influences energy density?

Pack design (cell‑to‑pack ratio), electrode materials, and packaging efficiency.

7. Key Takeaways & Next Steps

- Recap: Prioritize Wh/kg and Wh/L, not just Ah, to find the most efficient, lightweight pack.

- Next Steps:

1. Look up the energy density specs (Wh/kg & Wh/L) of candidate batteries.

2. Match chemistry to your tool’s runtime, temperature, and load requirements.

3. Consult manufacturer datasheets and independent test reports to finalize your choice.

Choosing the right energy‑dense battery ensures your power tool works harder, longer, and more comfortably all day on the job.