Customizable DEW 12–20V BMS PCBA for DeWalt DCB120, DCB201, DCB203, DCB204, DCB205 Battery Packs

Suitable for DeWalt 12V-20V Battery BMS PCBA, featuring overcurrent, overcharge, overheat, and over-discharge protection, anad custom solutions are available.Factory direct sales, welcome to learn and exchange ideas anytime.

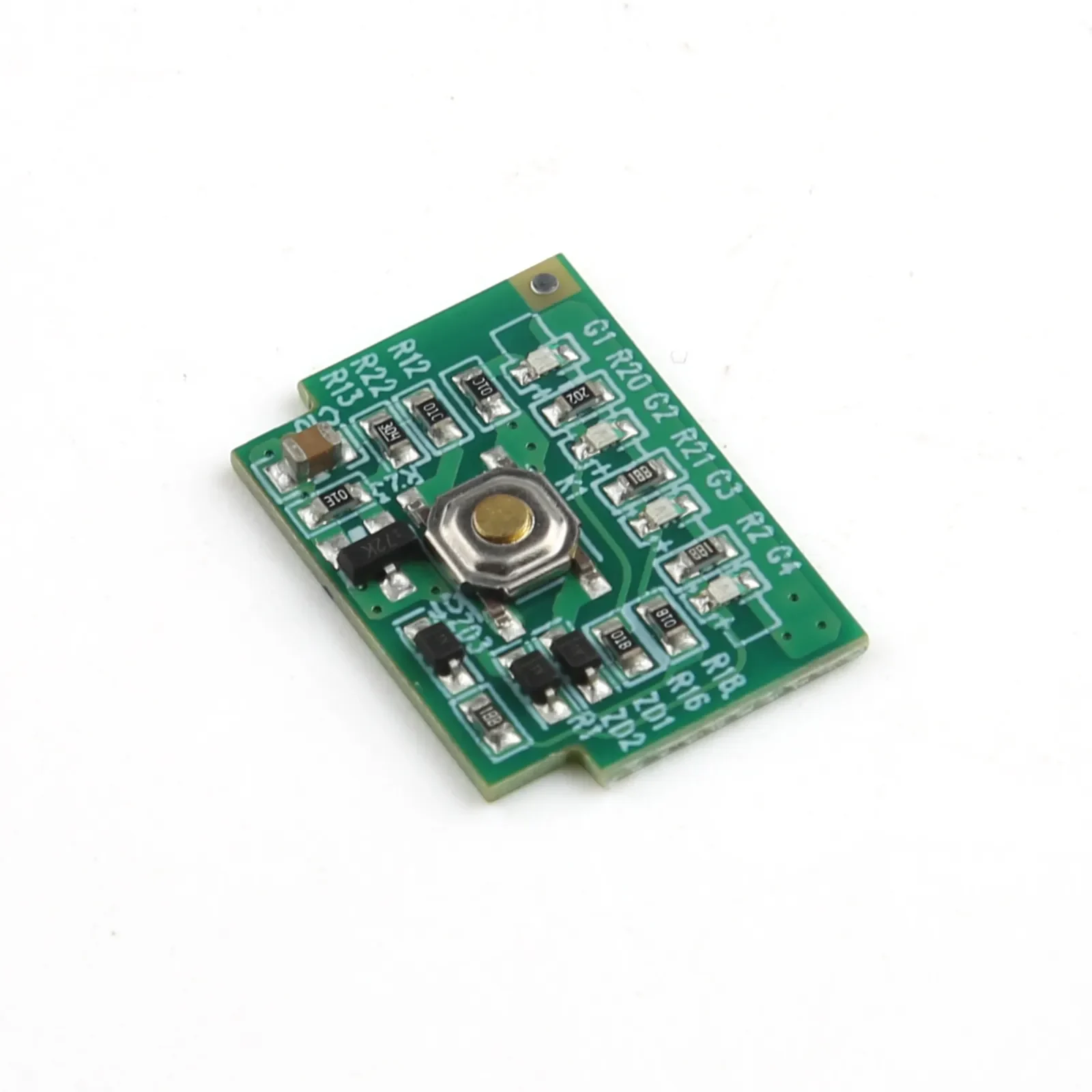

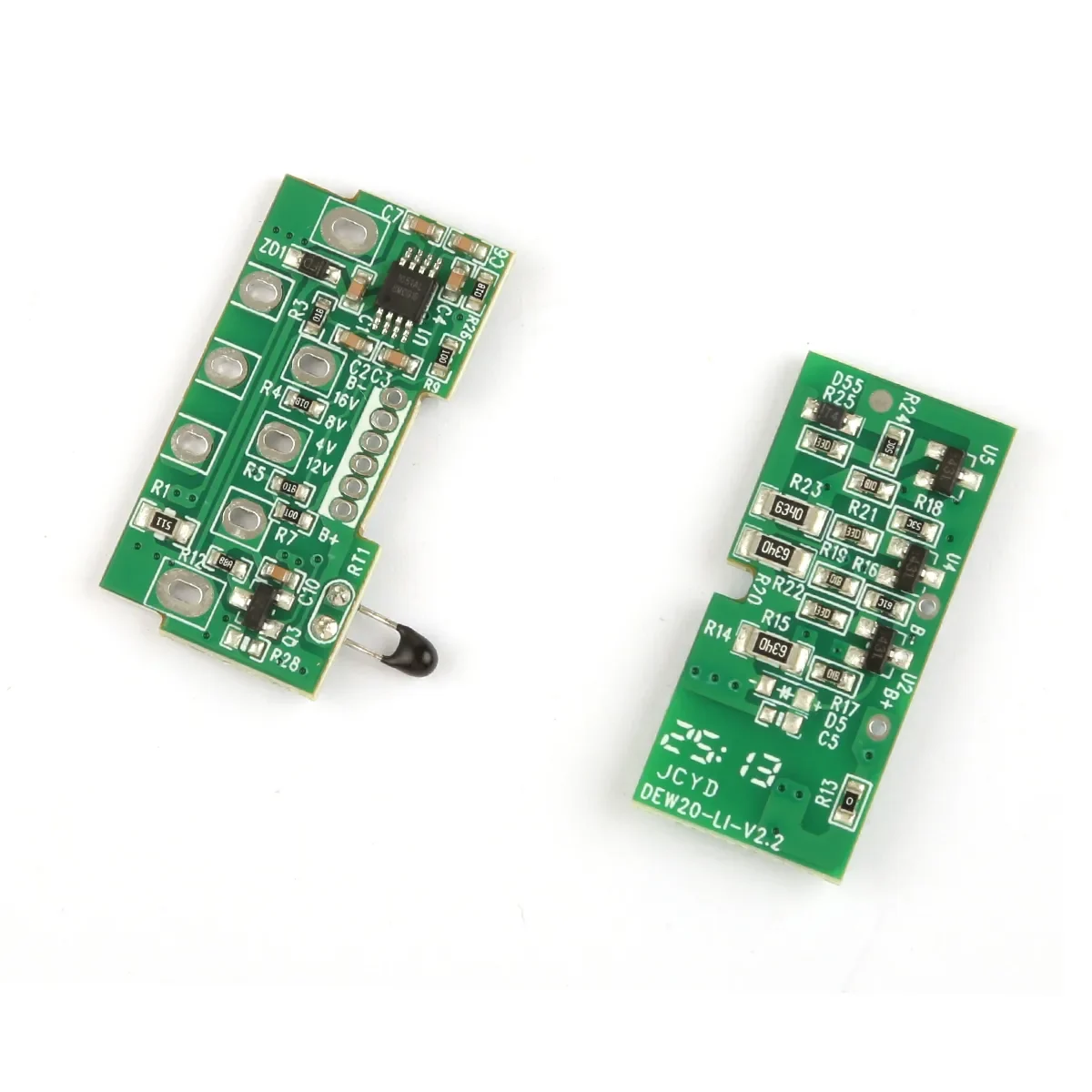

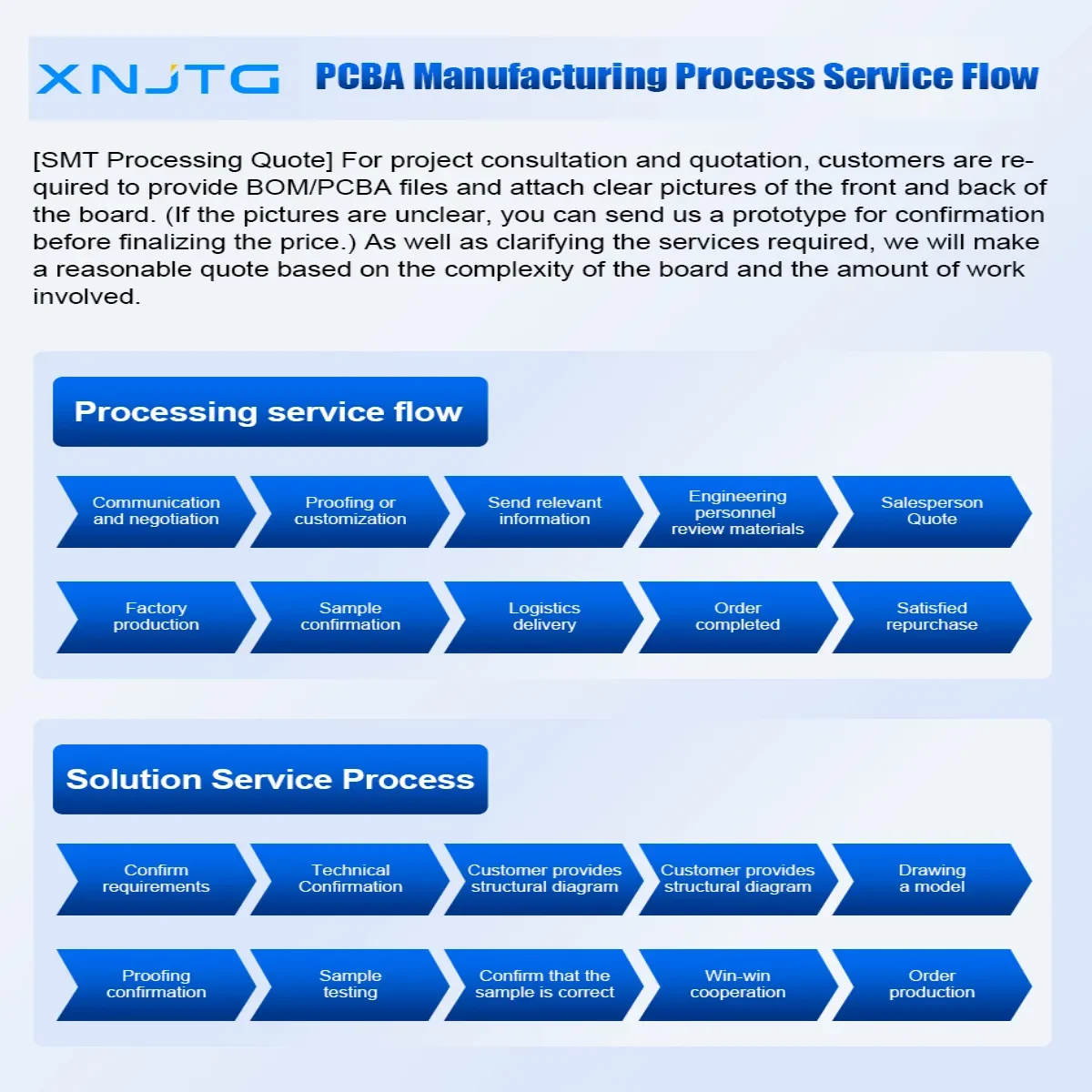

DEW-BMS-PCBA is a factory-grade Battery Management System (BMS) printed circuit board assembly engineered for DeWalt-style packs across the 12V–20V family. Designed for repair shops, pack builders, OEM integrators and advanced technicians, the board delivers the protections and monitoring necessary for safe charging, heavy-load discharge and long service life. It is supplied as a compact, board-level module suitable for direct replacement or integration into rebuilt or custom battery packs; XNJTG also offers customization services for adaptation to different connector types, current ratings and mechanical mounting constraints. (xnjtg.com)

Product overview and core protections

At its core, DEW-BMS-PCBA provides the essential protections expected of a modern lithium-ion BMS: over-charge (over-voltage) protection, over-discharge (under-voltage) protection, over-current / short-circuit protection and thermal / over-temperature protection. These protections work together to prevent the conditions that damage cells or create safety hazards—detecting unsafe voltages, currents or temperatures and disconnecting or limiting pack operation when thresholds are exceeded. The design is optimized to tolerate the high peak currents typical of power tools while preserving cell health through controlled management. (MathWorks)

Cell monitoring and balance management

DEW-BMS-PCBA continuously monitors individual cell taps and pack current so the system can detect imbalance, cell drift or a failing cell early. Where balancing circuitry is provided on the board, the BMS will perform cell balancing (passive or active depending on configuration) to keep cell voltages aligned, which maximizes usable pack capacity and extends cycle life—an especially valuable feature in packs rebuilt from multiple 18650/21700 cells or when cells of varying age/capacity are used. Properly implemented cell balancing prevents repeated overcharge/over-discharge of weaker cells and reduces long-term degradation.

Compatibility, customization and use cases

DEW-BMS-PCBA targets DeWalt 12V–20V form factors and is suitable both as a direct BMS replacement for common DeWalt packs and as the management core for rebuilt or custom packs intended to match DeWalt output/connector conventions. Typical use cases include: (1) replacing a failed OEM BMS to restore an otherwise serviceable pack, (2) rebuilding aged packs with fresh cells and a reliable protection subsystem, and (3) building custom high-discharge 12V/18V/20V packs for special applications that require enhanced capacity or different cell configurations. XNJTG’s factory-direct model and custom solutions mean threshold settings, connector pinouts, mechanical mounting and current capability can be adapted for production or small runs. (xnjtg.com)

Installation, integration and testing guidance

DEW-BMS-PCBA is a board-level component and must be integrated by personnel familiar with battery assembly and safety practices. The BMS must be matched to the pack topology (series cell count and any parallel groups), and every cell tap, temperature sensor and main output must be wired to the correct terminal. Use cells of the same chemistry, capacity and similar state-of-health; ensure secure busbar/nickel-strip welds or reliable solder joints, robust insulation, and appropriate mechanical strain relief. After assembly, verify the pack with these tests: open-circuit cell voltages; balance-wire continuity; a low-current charge/discharge validation; controlled over-current trip testing; and a thermal check under expected tool load. These steps help confirm that protection thresholds engage correctly and that the pack behaves predictably when stressed. (Monolithic Power)

Safety notes and recommended best practices

Because DEW-BMS-PCBA is designed for high-energy lithium-ion packs, safety is critical. Do not operate packs that are swollen, leaking, or showing abnormal voltages. Never bypass the BMS protections or exceed the board’s rated continuous or peak current. Store and charge packs in appropriate conditions, avoid mechanical shock, and observe local regulations for battery handling and transport. For commercial or end-user products, confirm required certifications and testing (electrical safety, transport compliance and any regional standards) before shipping or selling finished packs.

Why choose DEW-BMS-PCBA

DEW-BMS-PCBA gives technicians a compact, proven protection subsystem that reduces development time and restores safety to repaired packs. It reduces waste and cost by enabling targeted BMS replacement instead of full pack replacement, and it makes custom pack builds practical by centralizing protections, monitoring and (where fitted) balancing. For repair centers and small manufacturers, XNJTG’s ability to provide board-level modules and custom adaptation shortens the path from prototype to production. (xnjtg.com)