Suitable for Makita 10.8V-18V BMS PCBA BL1860 / BL1850 and other Makita battery packs — Protection boards and customization services

Suitable for Makita 10.8V-18V Battery BMS PCBA, featuring overcurrent, overcharge, overheat, and over-discharge protection, and custom solutions are available.

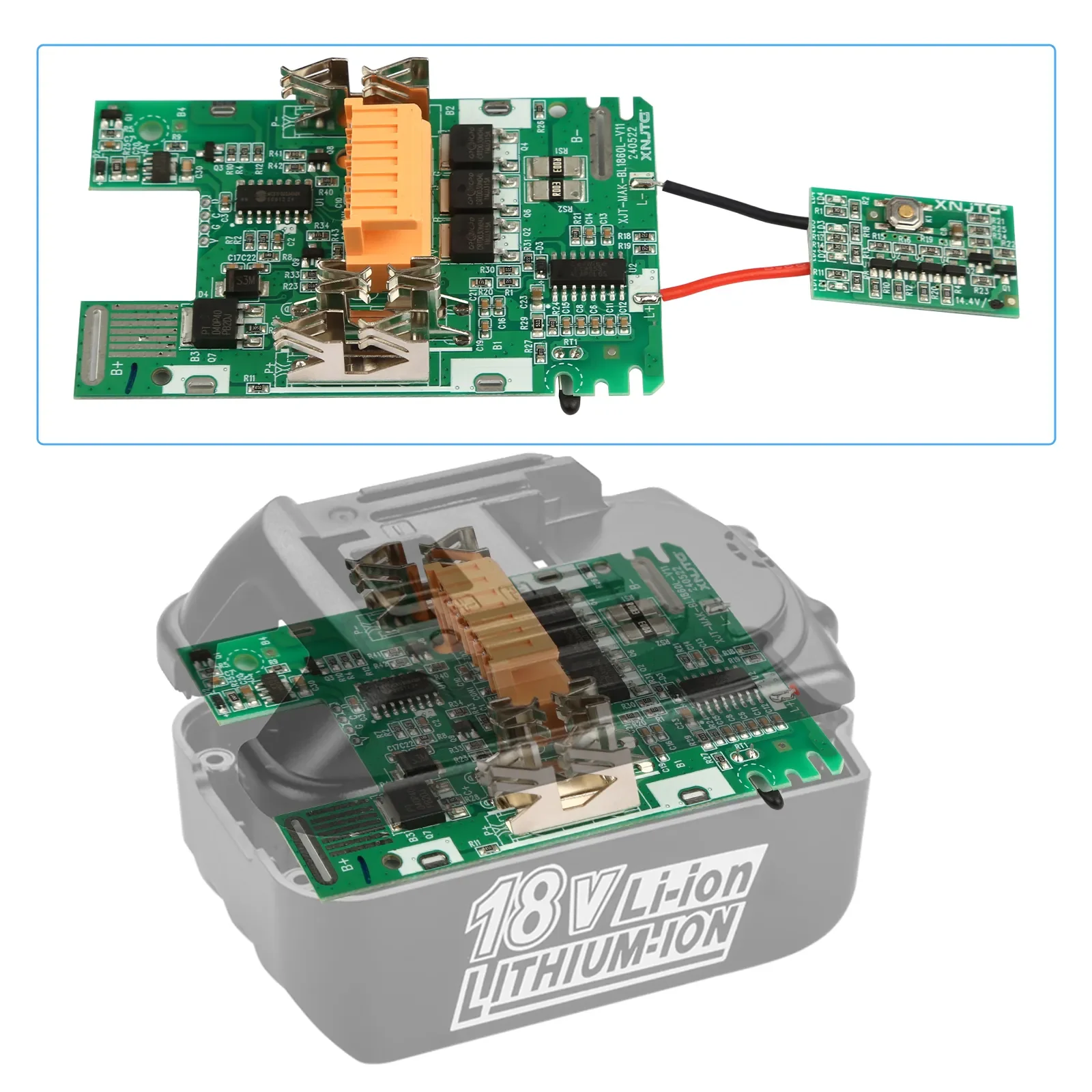

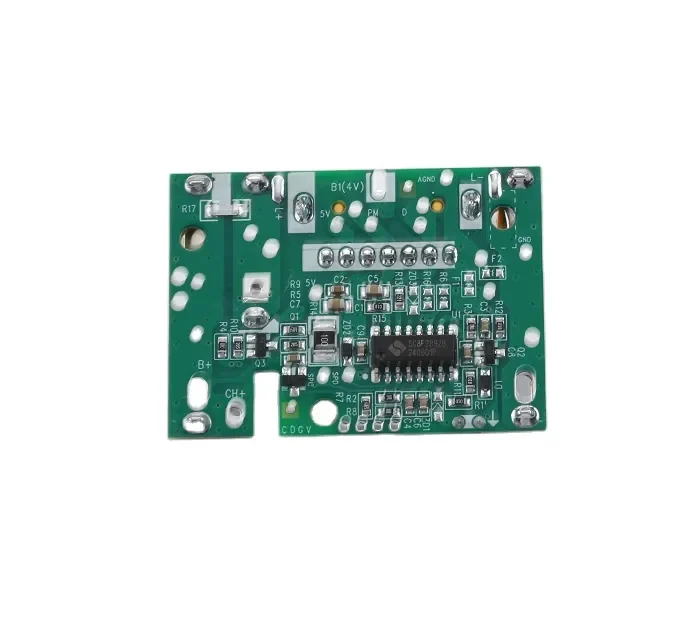

MAK-PCBA is a purpose-built Battery Management System (BMS) printed circuit board assembly designed to bring reliable, intelligent protection and control to Makita 10.8V-18V lithium-ion packs (including common models such as BL1860 and BL1850 etc.) and compatible 10.8V-18V tool battery assemblies. Engineered for repair shops, pack builders, OEM integrators and advanced DIYers, MAK-PCBA consolidates cell monitoring, thermal sensing, current control and cell balancing into a compact, robust board so a rebuilt or replacement pack behaves safely and predictably under the heavy loads typical of power tools.

Key capabilities

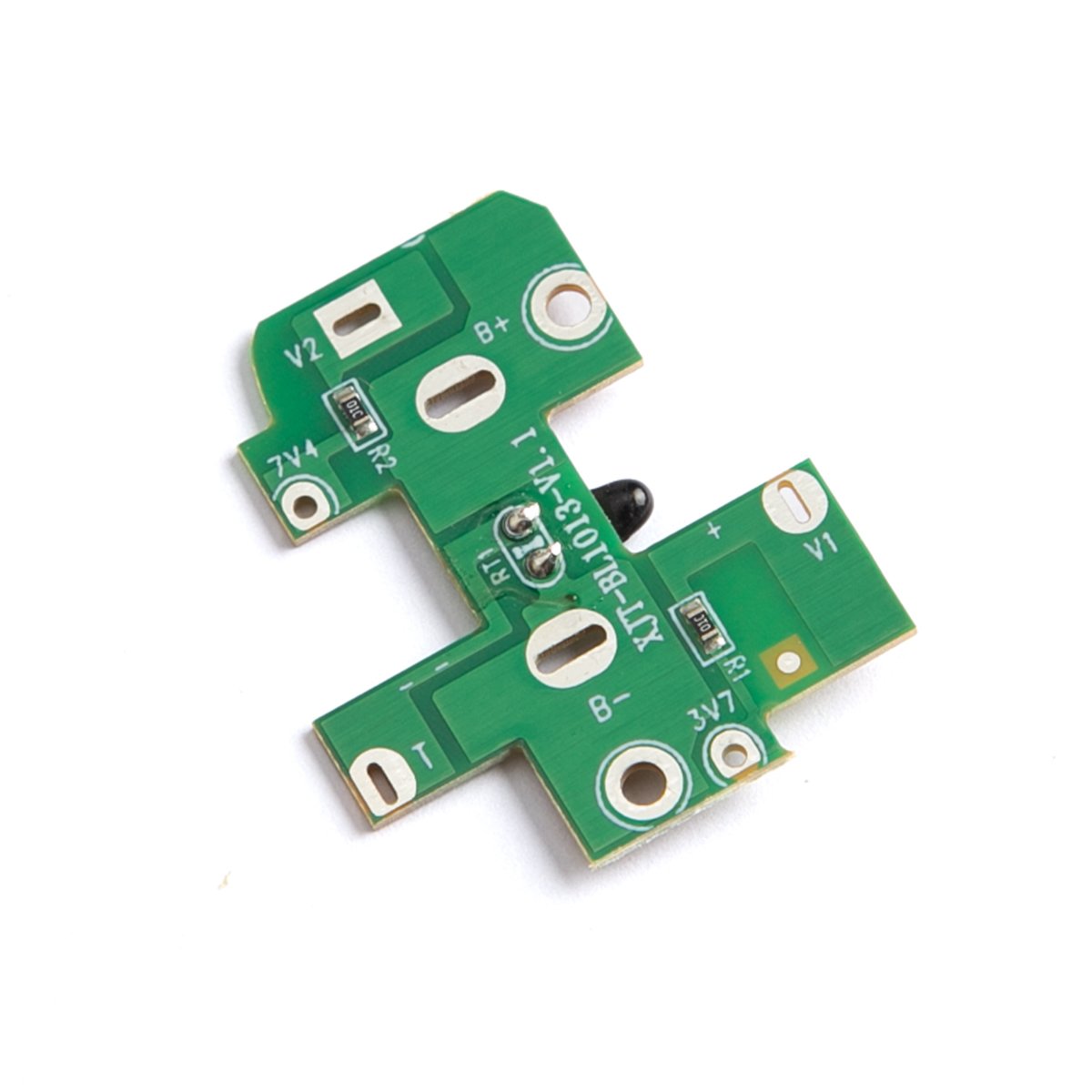

MAK-PCBA implements the full set of protections expected of a modern BMS: over-charge and over-voltage protection to prevent cell damage during charging, over-discharge / under-voltage protection to avoid irreversible cell degradation during deep discharge, over-current and short-circuit protection for safe operation under heavy tool loads, and thermal protection via integrated temperature sensing to guard against overheating and thermal runaway. The board continuously monitors individual cell voltages and pack current, and when equipped with balancing circuitry it equalizes cell voltages to maximize usable capacity and extend cycle life. The result is a pack that charges, discharges and delivers high peak current while maintaining safety margins and predictable behavior across charge cycles.

Compatibility and customization

MAK-PCBA is built with Makita 18V form-factor packs in mind and is compatible with the electrical and mechanical expectations of BL1860/BL1850 style packs; it is suitable for direct BMS replacements, brand new packs using 18650/21700 cells, and new pack designs that require Makita-style output and connector arrangements. Recognizing the variety of pack topologies and user requirements, XNJTG offers custom solution services: protection thresholds, balancing approach, connector types, and mechanical mounting can be adapted to match specific cell counts, series/parallel configurations, current ratings and enclosure constraints. This flexibility makes MAK-PCBA suitable for repair, small-batch manufacturing, and bespoke pack engineering.

Typical applications

Use MAK-PCBA when you need to replace a failed OEM BMS, rebuild an aged Makita-format battery pack, or build a custom high-discharge 18V pack for tools and professional applications. It is especially useful where restoring pack functionality is more cost-effective than replacing the entire pack, or where tailored protection and monitoring behavior is required for non-standard cell sets or increased capacity designs. The board’s protections and balancing functionality also make it an appropriate choice for service centers and technicians who rebuild and test large numbers of packs.

Benefits

Adopting MAK-PCBA delivers clear operational and economic advantages: it restores safety and protection to damaged or non-functional packs, reduces waste and replacement cost by enabling targeted BMS replacement, and improves pack longevity through active balancing and thermal management. For integrators, the board reduces development time and risk by providing a proven protection subsystem that can be quickly validated under real loads. For end users, the result is a battery that charges reliably, delivers consistent runtime, and responds safely to tool demands.

Installation and integration guidance

MAK-PCBA is a board-level product and must be integrated by personnel familiar with battery pack assembly and safety practices. The BMS must be matched to pack topology (cell count, series/parallel arrangement) and properly connected to all cell taps, temperature sensors and main output terminals. Use identical or closely matched cells (same chemistry, capacity and age) to avoid imbalance stress; ensure secure busbar / nickel strip welds or reliable soldering where appropriate, and confirm insulation, mechanical retention and strain relief to prevent connector failure. After assembly, validate the pack with a sequence of tests: open-circuit cell voltages, balance line continuity, low-current charge/discharge verification, over-current protection test under controlled conditions, and thermal behavior under expected load. Always follow local regulations for battery handling, transport and disposal.

Safety notes and best practices

Because MAK-PCBA is designed for high-energy lithium-ion packs, safety is paramount. Do not operate a pack that is swollen, leaking, producing odor, or showing abnormal voltages. Never bypass BMS protections or attempt to drive the board beyond its rated current and temperature specifications. Store and charge batteries in appropriate environments, avoid mechanical shock and exposure to moisture, and use chargers compatible with Makita 18V pack chemistry and nominal voltage. If uncertain about integration or testing procedures, con