MIL-BMS-PCBA — Pro-Grade Battery Management Board for Milwaukee M-12 M-18 Packs

Suitable for Milwaukee 10.8V-18V Battery BMS PCBA, featuring overcurrent, overcharge, overheat, and over-discharge protection, and custom solutions are available.

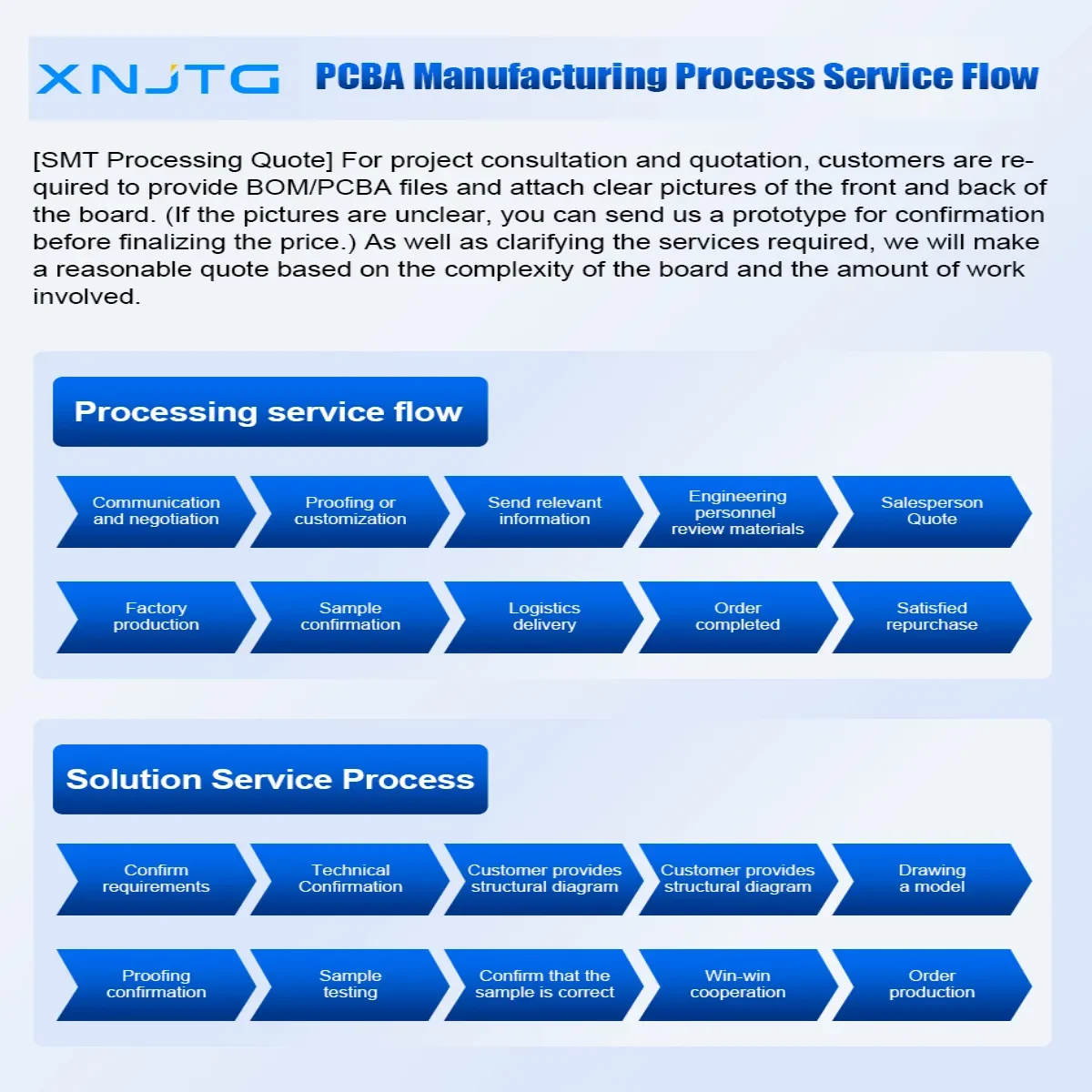

We can meet most of your needs. Having completed over 5,000 projects, we have a deep understanding of our clients' diverse requirements. We are a factory direct supplier, and you are always welcome to come and learn from us and collaborate with us.

XNJTG MIL-BMS-PCBA is a factory-grade Battery Management System (BMS) printed circuit board assembly engineered for Milwaukee-style packs across the 10.8V–18V / M-12 / M-18 / REDLITHIUM family. Supplied as a compact, board-level module, it is intended for direct replacement in compatible packs, integration into rebuilt battery assemblies, or inclusion as the protection core in small-batch production. XNJTG positions this board for repair shops, pack builders, OEM integrators and advanced technicians and offers custom solutions to match connector pinouts, current ratings and mechanical constraints. (xnjtg.com)

What this board does (core capabilities)

At its heart, XNJTG MIL-BMS-PCBA implements the essential protections required of modern lithium-ion BMS designs: over-charge (over-voltage) protection, over-discharge (under-voltage) protection, over-current / short-circuit protection and thermal / over-temperature protection. These protections continuously monitor voltages, currents and temperature and disconnect or limit pack operation when unsafe conditions are detected, preventing cell damage and reducing fire risk. The board is designed to tolerate the short, high peak currents typical of cordless power tools while protecting overall pack health. (xnjtg.com)

Cell monitoring and balance management

XNJTG MIL-BMS-PCBA monitors individual cell taps and pack current so the system can detect imbalance, cell drift or failing cells early. Where balancing circuitry is included (passive or active depending on the SKU), the BMS equalizes cell voltages to maximize usable capacity and extend cycle life — a critical feature when rebuilding packs from 18650/21700 cells or when cells of differing age are present. Active balancing techniques can shift charge between cells for higher efficiency, while passive balancing safely bleeds off excess cell charge when appropriate. Balanced cell voltages help avoid repeated over-charge / over-discharge of weaker cells and prolong pack lifespan.

Compatibility, supported battery models and typical use cases

🔧 Supported / Compatible Milwaukee Battery Packs

XNJTG MIL-BMS-PCBA is designed with the Milwaukee M-12 M-18 / 18V (10.8V–18V) battery ecosystem in mind, and is compatible with a broad range of pack types including, but not limited to:

-

REDLITHIUM™ Compact / CP series (e.g. 48-11-1815, CP 1.5 Ah / CP 2.0 Ah) (batteryequivalents.com)

-

REDLITHIUM™ “CP2.0 / CP3.0 / Compact” small packs used for light tools and compact drills. (batteryequivalents.com)

-

REDLITHIUM™ XC / Extended Capacity packs (e.g. 3.0Ah, 4.0Ah, 5.0Ah, 6.0Ah) for tools requiring longer runtime. (batteryequivalents.com)

-

REDLITHIUM™ High Output (HO) and HD / High-Demand packs for heavy-duty tools, high current draw applications and extended load demands (as long as pack shape, cell count and tap layout match). (batteryequivalents.com)

Because all packs in the Milwaukee M-12 M-18 (10.8-18V) line share a standardized pack form factor and busbar / tap architecture for that line, XNJTG MIL-BMS-PCBA is expected to fit and function in any of the above when assembled / wired correctly.

📦 Typical Use Cases

-

Direct BMS replacement for existing Milwaukee packs whose original BMS has failed or degraded, thereby extending battery pack life.

-

Rebuilt battery pack construction — using new 18650 / 21700 cells to build a pack with Milwaukee-compatible physical form, and using XNJTG MIL-BMS-PCBA to manage and protect the cell group.

-

Custom or small-batch pack production — for OEMs, repair shops or pack-builders needing to make non-standard or high-capacity packs but wanting a tested BMS backbone.

Installation, integration and validation guidance

XNJTG MIL-BMS-PCBA is a board-level component and must be integrated by personnel experienced in battery pack assembly and safety procedures. Key integration and validation steps include: confirm the BMS matches your pack topology (series count and any parallel groups); wire every cell tap, pack positive/negative and temperature sensor correctly; use secure busbar/nickel-strip welds or sound solder joints; provide mechanical strain relief and insulation. After assembly, validate the pack with a sequence of tests: open-circuit cell voltages, balance-wire continuity, low-current charge/discharge verification, controlled over-current trip testing and thermal checks under expected tool load. Thorough validation under realistic stress profiles prevents field failures and confirms protection thresholds operate as intended.

Safety notes and recommended best practices

Because XNJTG MIL-BMS-PCBA is intended for high-energy lithium-ion packs, safety is paramount. Do not use or attempt to repair packs that are swollen, leaking, emitting unusual odors, or showing extreme cell-to-cell voltage differences. Never bypass BMS protections or operate the board beyond its rated continuous or peak current and temperature limits. Use matched cells (same chemistry, capacity and similar state-of-health) when rebuilding packs. For commercial products, ensure appropriate electrical safety testing and transport compliance before shipping finished battery products.

Why choose XNJTG MIL-BMS-PCBA

XNJTG MIL-BMS-PCBA provides a compact, proven protection subsystem that reduces time-to-repair, lowers replacement cost and enables safe, repeatable pack rebuild workflows. Instead of discarding packs for a failed protection board, technicians can perform targeted BMS replacement to restore service. For OEMs and pack builders, XNJTG’s customization capability shortens the path from prototype to small-batch production by offering tailored thresholds, connector options and mechanical layouts. When integrated and validated correctly, XNJTG MIL-BMS-PCBA restores safety, predictability and longevity to Milwaukee-format battery packs — whether compact, extended capacity, or high-demand variants.