Resources

Blog

Guard Your BMS: Ultimate Guide to ESD Protection in PCBA Assembly

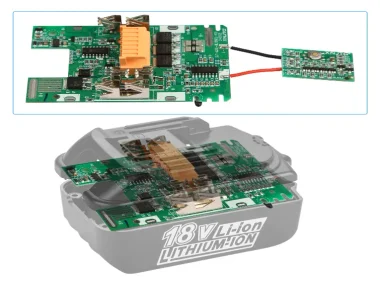

A Battery Management System (BMS) PCBA integrates precision components—MOSFET arrays, high-accuracy sense resistors, gate drivers, protection ICs, MCUs, and analog front ends—designed to monitor and regulate lithium-ion battery packs. These devices operate at low voltage thresholds and contain semiconductor junctions only microns thick. Electrostatic discharge (ESD) introduces sudden, high-voltage, high-current pulses capable of damaging these structures instantly or causing latent defects that fail months later. In power-tool, e-bike, vacuum, and energy-storage battery production, rigorous ESD control directly determines pack safety, lifecycle, and failure rate.

PCB vs PCBA — Clear Definitions, Key Differences, and Use Cases

Understanding the difference between a PCB (bare board) and a PCBA (populated assembly) is critical for design, manufacturing, and troubleshooting. This guide explains what each is, their technical attributes, failure modes, DFM considerations, and when to order one versus the other.

PCBA Manufacturing Process Technology

This article explains practical PCBA manufacturing technology from incoming-material checks through final testing on a standard SMT/assembly line. It focuses on measurable, repeatable floor-level controls that directly affect solder quality, placement accuracy, reflow stability, inspection predictability and reproducible diagnostics used by engineers and technicians on real production floors. The goal is to outline methods that work on factory equipment—not lab-only instrumentation.

DeWalt Pack “Fully Charged” but Drains Fast: Diagnostics & Actions

When a battery shows “fully charged” but loses runtime quickly, it usually indicates a mismatch between SOC display and actual capacity. Causes include high DCIR, cell imbalance, BMS miscalibration, poor contacts, or failing cells. This guide provides safe diagnostics, pass/fail criteria, CSV logging fields, and operational actions.

Why Some Milwaukee M18 Packs Fail to Wake Up After Complete Drain

A fully drained M18 pack that refuses to “wake”—no charger LED, no current acceptance, or tool fault—usually indicates the pack’s BMS latched, one or more cells are severely discharged, or the charger-tool handshake fails. This guide explains safe triage, practical recovery, and field-level diagnostics to assess and possibly revive the pack.

DeWalt Charger Failure Symptoms Caused by Line-Voltage Instability

Mains voltage fluctuations—including sags, surges, frequency deviations, harmonics, and flicker—can silently degrade or disable DeWalt chargers. Common manifestations include erratic LEDs, intermittent charging, unusual noise, and overheating. This guide details technical causes, reproducible diagnostic steps, and engineering mitigation strategies for workshops, fleets, and field teams.

How Tool Motor Efficiency Impacts Milwaukee Battery Runtime

Motor efficiency—the fraction of electrical input converted into useful mechanical work—directly determines battery load. When motor or drive efficiency drops, the tool demands higher current for the same job. Higher current increases I²R heat, accelerates DCIR rise, triggers thermal limits sooner, and shortens Milwaukee M18 runtime. This guide explains the physics, provides field-measurable indicators, offers practical diagnostics without lab equipment, and clarifies whether the fix belongs to the tool, battery, or operations.

Why DeWalt 20V Packs Shut Off Under High Torque Loads

High-torque cordless tools create extremely fast, high-magnitude current spikes. When a DeWalt 20V pack suddenly cuts out, it is almost always a protective response triggered by voltage sag, overcurrent, thermal rise, or BMS logic—not a random failure. This guide explains the electrical chain behind shutdowns, provides reproducible field→bench→lab diagnostic steps, outlines root causes, and offers operational and engineering strategies for prevention.

Why Milwaukee M18 Packs Get Hotter on Certain Tools

Milwaukee M18 batteries can run hotter on some tools due to load profile, internal resistance, BMS behavior, and tool electronics. Understanding these factors helps users diagnose, mitigate, and extend pack life safely. This guide includes temperature thresholds, load references, and safe inspection practices.

Safe Testing Methods — DeWalt Charger Shows Solid Red Light

A solid red LED on a DeWalt charger is typically a protective lockout, triggered by factors such as battery over-temperature, BMS protection, unstable AC input, or internal charger safety latches. Understanding the underlying mechanisms allows field technicians and users to safely diagnose issues without opening the charger or risking personal injury. This guide provides step-by-step, non-destructive tests, detailed interpretations of observed behavior, and recommended logging practices for repeatable troubleshooting.

Connector Keying Differences Across Top Tool Brands

Mechanical connector keying and pin-sequencing strategies vary significantly across major power-tool brands, and these differences dictate orientation safety, signal-before-power behavior, insertion durability, and whether aftermarket packs or chargers operate reliably. This expanded guide details keying families, brand tendencies, structural tolerances, measurable QA methods, field inspection checklists, reproducible bench/lab tests, numeric acceptance gates, procurement wording, and CSV/report formats required for safe cross-brand compatibility validation.

Not All Tool Are Equal: How Your Choice Cuts Makita Battery Life Short

Not all tools treat batteries equally. Drills, grinders, hammers, and demolition tools stress cells differently, driving uneven aging, internal resistance growth, and early cutouts. Fleet reliability and pack life depend on understanding these tool-specific stress profiles, allocating the right battery types, and enforcing logging, testing, and procurement practices to maximize cycle life.

Let our battery power your success

Transform your path to success with our advanced battery technologies, while enjoying the perks of free technical guidance and tailored design services to meet your unique requirements.