Resources

Blog

How Protective Circuits in Makita Packs Prevent Overload Damage

Makita-style packs use layered hardware+firmware protections—current sensing, fast MOSFET disconnects, I²t/time-integral trips, thermistors, fuses and charger handshakes—to detect and stop shorts, sustained overloads and thermal faults. Field→bench diagnostics (swap test, OCV, time-resolved V(t)/I(t) traces, IR thermal mapping) separate pack vs tool failures. Never bypass protections; replace swollen or repeatedly-tripping packs. Immediate actions: run a swap test, capture a trip trace with current limiting, and IR-scan the stressed pack.

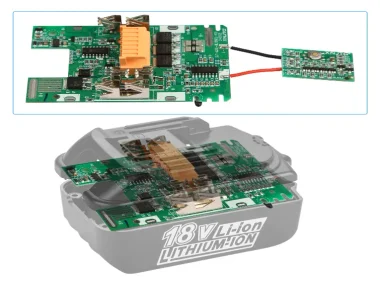

High-Reliability PCBA for Power Tools & Battery Management Systems (BMS)

High-reliability PCBAs for professional power tools and Battery Management Systems must survive extreme pulse currents, vibration, thermal cycling and wet/dusty environments while protecting users and cells. This article explains design principles, materials, manufacturing controls, reproducible test protocols and field triage practices that scale to volume production and reduce field failures — written to help engineering teams and volume buyers evaluate technical fitness without marketing fluff.

Makita BL Series Self-Discharge Rates After Long Storage

This article explains how Makita BL-series 18V batteries lose charge during long-term storage and why the observed “self-discharge” at pack level is higher than cell chemistry alone. It clarifies that apparent capacity loss includes both intrinsic cell self-discharge and continuous BMS quiescent currents, and shows how temperature, storage SOC, age, and handling conditions strongly affect the rate. The article outlines realistic monthly loss ranges under typical conditions, then provides reproducible field-to-bench measurement methods using controlled storage, OCV tracking, and low-rate capacity tests. It also defines practical warehouse thresholds, diagnostics, and best practices—such as storing at ~30–50% SOC and cool temperatures—to prevent deep discharge, BMS lockout, and unusable inventory after long storage.

Diagnosing Chargers That Charge Slowly or Incompletely

Slow or incomplete charging usually points to charger current-limit or regulation faults, battery BMS protection/high internal resistance, poor contacts, or thermal/firmware throttling. The guide outlines safe triage from field to bench: start with visual checks and charger–battery swap tests, then measure charge current, observe temperatures, and run controlled load and regulation tests. Common causes include aged electrolytic capacitors, handshake/wake-mode limits, thermal derate, or weak cells. Accurate isolation with current measurement and bench load testing determines whether to clean contacts, repair qualified charger components, or replace the battery or charger.

Temperature Sensing Placement in Makita Chargers — Why It Matters

Accurate temperature sensing in Makita-style chargers is essential for safe fast charging and correct charger–pack interaction. Thermistor or temperature IC placement directly affects detection speed, protection accuracy, derating behavior, and false trips. Best practice is multi-point sensing: pack-contact, charger hotspots (MOSFETs, transformer), and ambient, with strong thermal coupling, redundancy, calibration, and conservative control logic. Poor placement causes delayed protection, oscillation, reduced battery life, or safety risk; validation requires IR cross-checks, transient response tests, and fault-detection fallback logic.

Procedures & Methods for PCBA Testing

PCBA testing is the structured combination of non-destructive and destructive verification methods used to confirm that an assembled board meets electrical, functional, and reliability requirements. A well-designed test flow must not only detect assembly defects early but also screen borderline units that may fail under load, temperature, aging, or vibration. Mature manufacturers treat testing as an engineering discipline — one driven by data, fixture validation, failure-mode understanding, and traceability — rather than a simple pass/fail station. The following provides practical, defensible, and industry-standard testing procedures suitable for high-reliability products such as battery BMS boards, chargers, motor controllers, IoT modules, and power-management systems.

Beyond Assembly: A Transparent Walkthrough of Our High-Reliability PCBA Process for Power Solutions

High-reliability applications like battery management systems (BMS) and power tools demand precise, repeatable, and controlled PCBA (Printed Circuit Board Assembly) processes. This guide provides a complete, end-to-end view of our PCBA workflow—from bare PCB to fully tested and programmed modules—covering critical controls, reproducible checks, common defects, and troubleshooting.

Principles and Applications of PCB & PCBA Test Fixtures

Test fixtures are the mechanical and electrical interfaces that allow PCB/PCBA assemblies to be measured, exercised, and validated in production, R&D, and repair. A well-designed fixture converts a fragile board into a stable testable unit: it ensures repeatable electrical contact, protects the DUT (device under test), and routes signals safely to instruments or automated test software. This article explains fixture fundamentals, common types, design details, reproducible test flows, and how to diagnose fixture-induced failures.

SMT in PCBA Manufacturing: Process, Controls, and Best Practices

Surface Mount Technology (SMT) is the automated process that transforms a bare PCB into a fully functional PCBA. SMT includes solder paste printing, precise component placement, reflow soldering, inspection, and defect management. It is essential for high-density, high-yield, and reliable electronics, including BMS, power tools, and consumer devices.

Guard Your BMS: Ultimate Guide to ESD Protection in PCBA Assembly

A Battery Management System (BMS) PCBA integrates precision components—MOSFET arrays, high-accuracy sense resistors, gate drivers, protection ICs, MCUs, and analog front ends—designed to monitor and regulate lithium-ion battery packs. These devices operate at low voltage thresholds and contain semiconductor junctions only microns thick. Electrostatic discharge (ESD) introduces sudden, high-voltage, high-current pulses capable of damaging these structures instantly or causing latent defects that fail months later. In power-tool, e-bike, vacuum, and energy-storage battery production, rigorous ESD control directly determines pack safety, lifecycle, and failure rate.

PCB vs PCBA — Clear Definitions, Key Differences, and Use Cases

Understanding the difference between a PCB (bare board) and a PCBA (populated assembly) is critical for design, manufacturing, and troubleshooting. This guide explains what each is, their technical attributes, failure modes, DFM considerations, and when to order one versus the other.

PCBA Manufacturing Process Technology

This article explains practical PCBA manufacturing technology from incoming-material checks through final testing on a standard SMT/assembly line. It focuses on measurable, repeatable floor-level controls that directly affect solder quality, placement accuracy, reflow stability, inspection predictability and reproducible diagnostics used by engineers and technicians on real production floors. The goal is to outline methods that work on factory equipment—not lab-only instrumentation.

Let our battery power your success

Transform your path to success with our advanced battery technologies, while enjoying the perks of free technical guidance and tailored design services to meet your unique requirements.